Research Article - (2021) Volume 11, Issue 2

Abstract

The environmentally friendly technology for wheat grain processing and the equipment for its implementation have been considered. It has been established that in the production of cereals from wheat grain, the technology of dry cleaning of the grain surface is now widely used. The technique involves removing the upper layers of grain on hulling machines, making it possible to reduce microbiological contamination and pollution of grinding products with various contaminants. The proposed innovative technology consists of cleaning the grain, both outside the whole grain, and cleaning the surfaces hidden inside the grain after splitting it along the groove into two parts. This is achieved due to the possibility of access of the peeling machines' working bodies to the parts of the grain surface that are inaccessible before splitting. For the implementation of innovative technology, the equipment has been developed and manufactured, the energy intensity of which is lower than that for the production of cereals using traditional technology. According to the proposed innovative technology, a new grain product is formed – grain lobules obtained after splitting the grain along the groove, from which, after grinding, either a new type of elongated cereal corresponding to Poltavskaya No 2 is obtained, or wholemeal flour with low ash content, after additional peeling of the resulting cereal and grinding it in a vertical rotor hammer mill. Comparative outputs of cereal have been determined using well-known and innovative technology. It has been established that the output of wheat groats Poltavskaya according to the known technology is 51 %, Artek – 12 %, and husking bran – 30 %. According to innovative technology, the output of wheat groats Poltavskaya No 2 is 53 %, Poltavskaya No 4 – 28 %, and Artek – 3.2 %. When processing elongated grains into wholemeal flour, 48 % of wholemeal flour of increased biological value was obtained, without contaminants, which are contained in the groove of wheat and, during its classical processing, get into all types of flour. When grinding groats Poltavskaya No4 and Artek, the total output of wholemeal flour will increase to 79.2 % with an ash content of 0.72, which corresponds to the 1st-grade flour.

Keywords

Wheat grain; hulling; splitting; groove; grinding; aspiration; grinding; semi-finished grain product; wheat groats; flour.

Introduction

The nutritional status of the population, the quality, safety of food raw materials, and food products are of the most significant importance for maintaining and strengthening the population's health. In recent years, special attention has been paid to healthy nutrition, including food safety – biological, chemical, and radiation. Food safety refers to the quality of food products, indicating the absence of unacceptable risks associated with harmful effects on humans and future generations. A harmful effect on humans is exerted by factors associated with the presence of pollutants (contaminants) in food products such as radionuclides, toxins, pathogens that threaten human life or health (Bykova & Vaschenko, 2016; Roeva, 2009). Contaminated food currently includes a relatively large range of chemical substances (toxic elements, pesticides, nitrosamines, polychlorinated biphenyls), biological (mold microscopic fungi and mycotoxins, bacteria and bacterial toxins, yeast, seafood toxins) and physical nature, microbiological risks being on the first place (Beyer et al., 2006; Bykova & Vaschenko, 2016; Golinko & Levitskaya, 2013).

The grain is an organic compound consisting of anatomical parts of different structures and properties – endosperm, embryo, and membranes. Based on this concept, grain's technological properties can be subdivided into physicochemical, biochemical, structural, and mechanical. All these properties are in a complex relationship, typical for living organisms (Berkutova et al., 1964; Haddad et al., 1999; Edwards, 2010).

Wheat grain products are among the main products in the world (Uthayakumaran & Wrigley, 2010). Nowadays, grinding wheat grain into flour is mainly carried out according to a specific technological flow sheet (Butkovskiy & Melnikov, 1990; Butkovskiy & Melnikov, 1989; Vereschinskiy & Shevchenko, 2012; Anderson, 2011). First, the grain undergoes dry or wet cleaning, hydrothermal treatment, and the first brake system. Throughout this path of the technological flow sheet, before the grain enters the roller mill, the wheat grain remains intact. The grain of average total microbial count is 5∙106...8∙108 CFU/g (Bykova & Vaschenko, 2016). Primary dry cleaning, which includes sieve separation, aerodynamic, vibration-pneumatic separation, separation along the length and width, somewhat reduces contamination. This removes dust, diseased and injured grains that differ from healthy ones in weight and size, and superficial infection from healthy seeds. During wet secondary cleaning of grain, it is washing, part of the surface microbes is washed off with water. However, when interacting with water, a secondary infection of healthy grains occurs. Therefore, no noticeable decrease in infection is observed. The grain mass that entered the stage of hydrothermal treatment has an infection rate of 8∙106...1∙107 CFU/g (Beyer et al., 2006).

According to the research results of D.A. Fellers (1976) and A.I. Morgan (1966), and many other authors, the most effective method of dry cleaning of the grain surface is peeling, during which part of the surface layers of the grain is removed.

Many enterprises have begun to develop and implement dry cleaning technology, which consists in removing the upper layers of grain on hulling machines, which made it possible to reduce microbiological contamination and pollution with various chemical components (heavy metals, pesticides, and others), most of which are concentrated on the surface layers of the grain (hulls) (Bogomolov & Irkliienko, 2019). This technology is also used in the production of wheat groats.

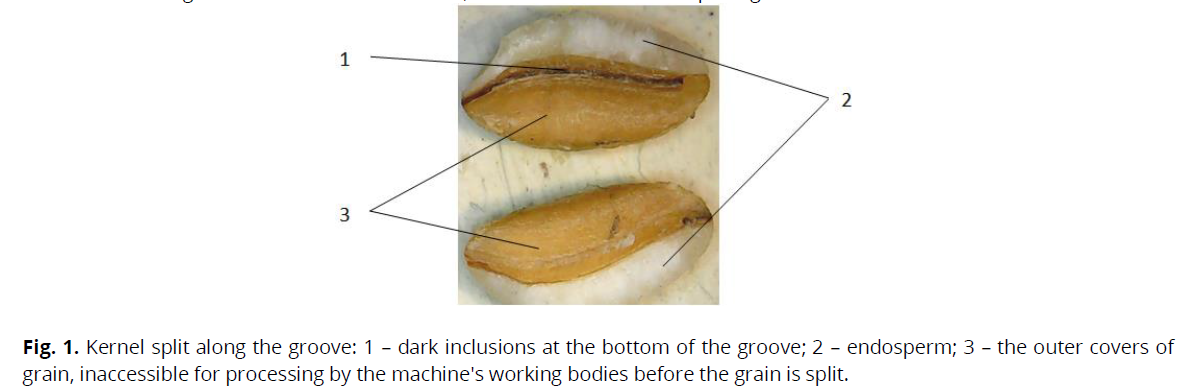

The article discusses an innovative, environmentally friendly technology of processing grain into cereals and flour, the essence of which lies in the technology of cleaning grain, both outside the whole grain and additional cleaning of hidden surfaces inside the grain, after splitting the kernels along the grooves, as shown in Figure 1 due to the possibility of access of the cleaning machines' working bodies to the kernel surfaces, are inaccessible before splitting.

Fig 1: Kernel split along the groove: 1 – dark inclusions at the bottom of the groove; 2 – endosperm; 3 – the outer covers of grain, inaccessible for processing by the machine's working bodies before the grain is split.

Particles (lobules) of grain split along the groove are shown in Fig. 1. Hidden surfaces (3) lying in the depth of the grain are visible in the picture. At the bottom of the groove, inclusions of a dark shade (1) are seen, the nature of which has not yet been studied (Bogomolov & Irkliienko, 2018; Bogomolov & Irkliienko, 2016).

Thus, by splitting the grain along the groove into two parts, we gain access to the newly formed surfaces, which can significantly reduce the grain's ash content (Bogomolov & Irkliienko, 2018). The assumption that these inclusions are contaminants is not unreasonable, and they, in any case, they undoubtedly increase the ash content of the grain; therefore, removing these inclusions in products is the main task of this research.

Materials and Methods

We used the wheat grain with the following parameters: initial moisture – 14 %; nature – 746 g/l; vitreousness – 60 %; mass of 1000 grains – 35.2 g and ash content – 1.75 %. Grain clogging did not exceed the limits for its processing into flour and cereals. The equipment used to implement the proposed technology was developed at the Department of Equipment and Engineering of Processing and Food Production of the KhNTUA.

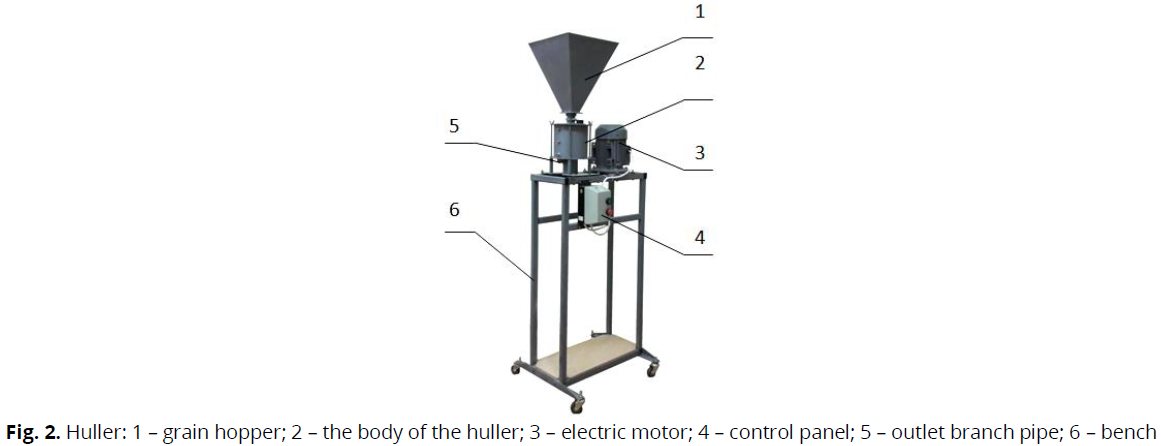

Peeling of grain was carried out in the huller with an abrasive cylinder and three abrasive disks. The general view of the machine is shown in Figure 2.

Fig 2: Huller: 1 – grain hopper; 2 – the body of the huller; 3 – electric motor; 4 – control panel; 5 – outlet branch pipe; 6 – bench

There is a grain hopper (1) in the upper part of the machine, which is located above the body (2) of the huller. The working body of the huller is driven by the electric motor (3). The control panel (4) is to turn the machine on/off. Products of peeling leave through the outlet branch pipe (5). All mechanisms are placed on a bench (6).

The degree of grain hulling depends on the speed of passage of products through the huller. As the speed decreases, the degree of grain hulling increases. The hulling degree was set in the range from 5 % to 6 % (Vereschinskiy, 2013; Mousia, et al., 2004; Vereschinskiy & Shevchenko, 2012; Vereschinskiy, 2011; Giambanelli et al., 2016).

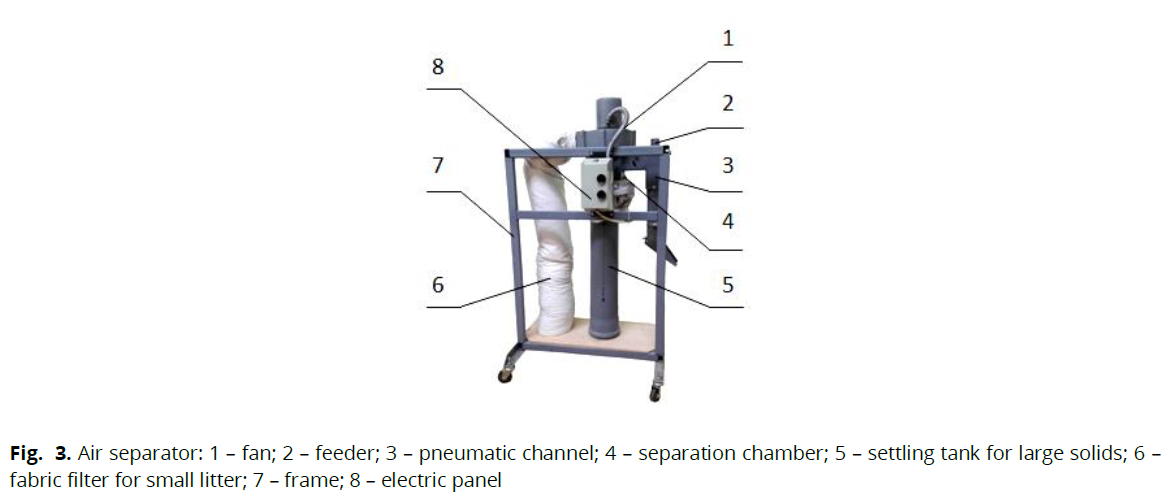

To clean the products from light impurities, an air separator (Figure 3) was developed, which consists of a fan (1) mounted on the frame (7), a feeder (2) made in the form of a pipe installed in the pneumatic channel (3). The pneumatic channel is connected to the separation chamber (4) with the fan inlet and at the bottom with a settling tank (5) for extensive screenings. At the outlet of the fan is located a fabric filter (6) for small litter.

Fig 3: Air separator: 1 – fan; 2 – feeder; 3 – pneumatic channel; 4 – separation chamber; 5 – settling tank for large solids; 6 – fabric filter for small litter; 7 – frame; 8 – electric panel

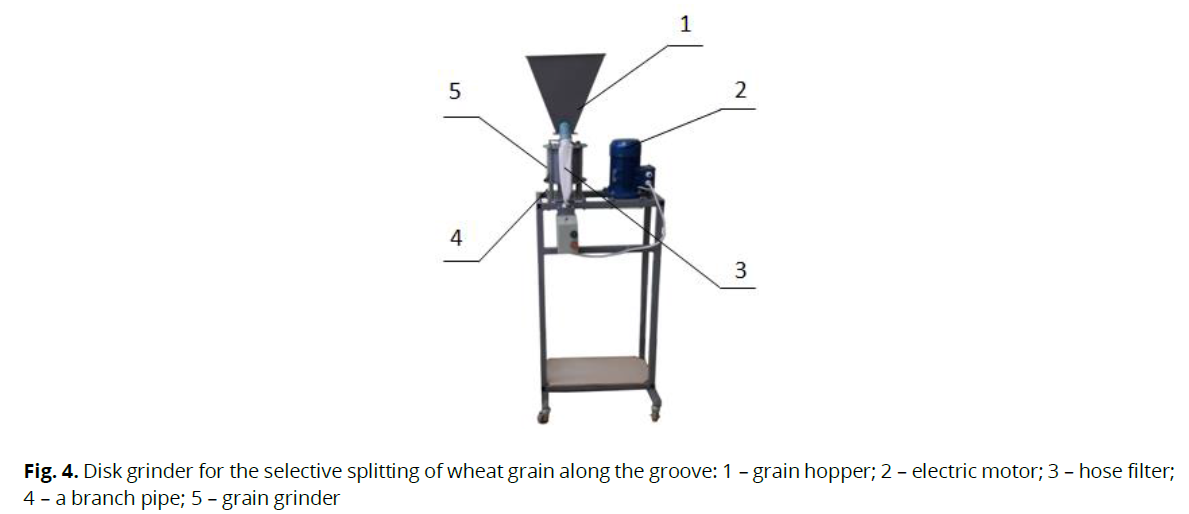

The air separator's efficiency is determined by the value of the specific load and the airflow speed in the pneumatic channel, its size, and the degree of clogging. The specific load value was mainly taken depending on the weight of the grains and set experimentally. For selective splitting of grain along a groove, the disk grinder was used (Figure 4).

Fig 4: Disk grinder for the selective splitting of wheat grain along the groove: 1 – grain hopper; 2 – electric motor; 3 – hose filter; 4 – a branch pipe; 5 – grain grinder

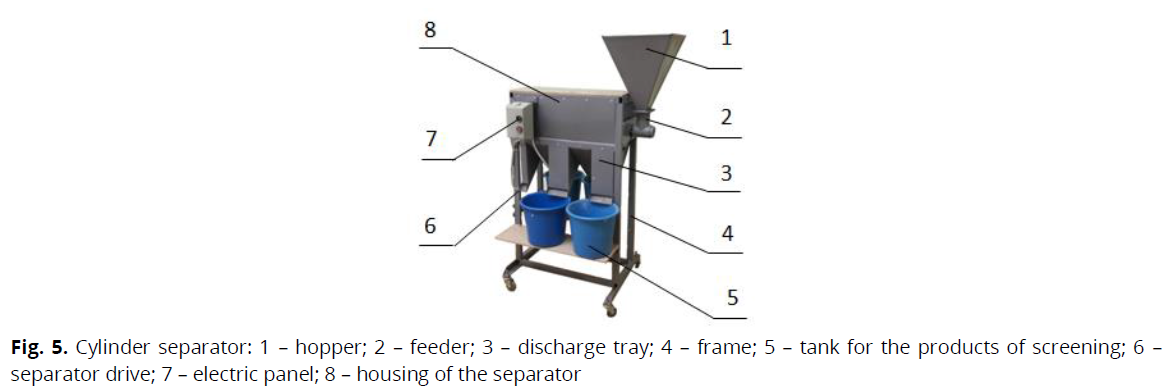

The shearing disk grinder consists of a loading hopper (1) through which the grain is fed to the grinder (5). The drive consists of a V-belt transmission, which transmits rotation from the motor (2) to the grinder's mobile disk. The output of the crushed product is carried out through the branch pipe (4). The dust fraction settles in the hose filter (3). The disk grinder's design could split wheat grains into two parts (slices) along the groove. The separation of grinding products was carried out on a cylinder separator (Figure 5), the working body of which consists of four cylindrical sieves. The size of the sieve holes increases as the product moves. The separator includes a separator housing (1), a drive (6), and an electric remote control (7) mounted on the frame (4). A loading hopper (1) with a feeder (2) and discharge trays (3) are fixed on the separator housing.

Fig 5: Cylinder separator: 1 – hopper; 2 – feeder; 3 – discharge tray; 4 – frame; 5 – tank for the products of screening; 6 – separator drive; 7 – electric panel; 8 – housing of the separator

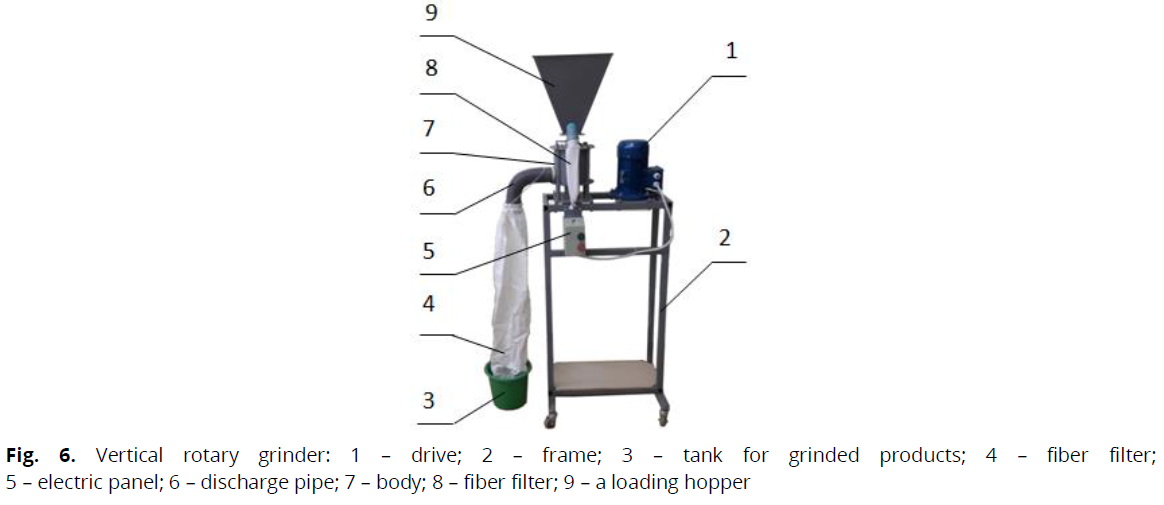

The crushed product can be separated into 2, 3, or 4 fractions using the cylinder separator. To grind the grain products into flour, the developed vertical rotary grinder was used. The vertical rotor grinder (Figure 6) has a vertical design and consists of a frame (2) on which the machine body (7), drive (1), and electric panel (5) are fixed. On the machine body, there is a loading hopper (9) for the product to be crushed, a fabric filter (4), and a discharge pipe (6), with a fabric filter (4) fixed on it, the lower part of which is lowered to the bottom of the tank (3).

Fig 6: Vertical rotary grinder: 1 – drive; 2 – frame; 3 – tank for grinded products; 4 – fiber filter; 5 – electric panel; 6 – discharge pipe; 7 – body; 8 – fiber filter; 9 – a loading hopper

Wholemeal flour with low ash content was obtained due to the application of the vertical rotary grinder.

Results and Discussion

Grinding is one of the most energy-intensive processes in the processing of wheat grain into flour and groats. The grinding process is determined by the action of external forces that cause deformation of the kernel and, as a consequence, its destruction. Shear is known to be the least energy-intensive among different types of load. This is discussed in many works devoted to the processing and grinding grain (Butkovskiy & Melnikov, 1990; Butkovskiy & Melnikov, 1989; Vereschinskiy & Shevchenko, 2012; Bogomolov & Irkliienko, 2016; Bogomolov & Irkliienko, 2018; Bogomolov & Irkliienko, 2019). As already mentioned, the grain's morphological structure allows it to be split selectively along the groove into two parts.

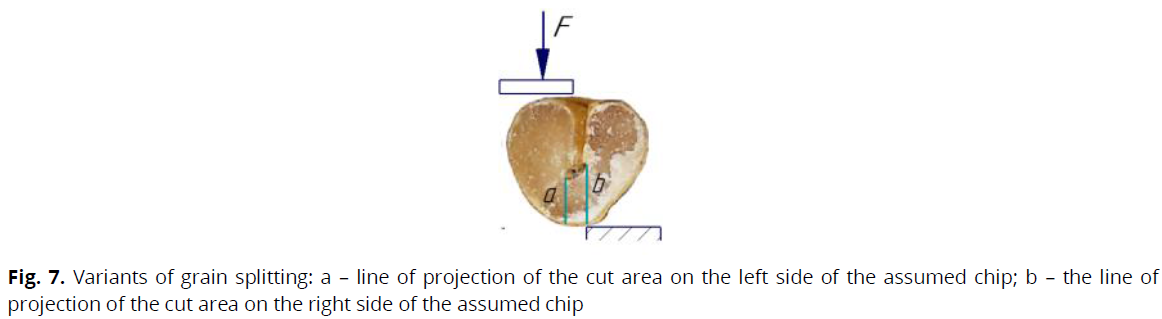

When loading the kernel, as shown in Figure 7, it splits (in an ideal situation) along the groove into two parts by sequentially shifting (splitting) one part of the kernel concerning the other.

Fig 7: Variants of grain splitting: a – line of projection of the cut area on the left side of the assumed chip; b – the line of projection of the cut area on the right side of the assumed chip

The action of shear stresses accompanies the shear, and when their critical value comes, the body is destroyed due to the displacement of one part for the other. When the internal stress reaches the kernel's ultimate strength, its destruction occurs (Konovalov et al., 2015).

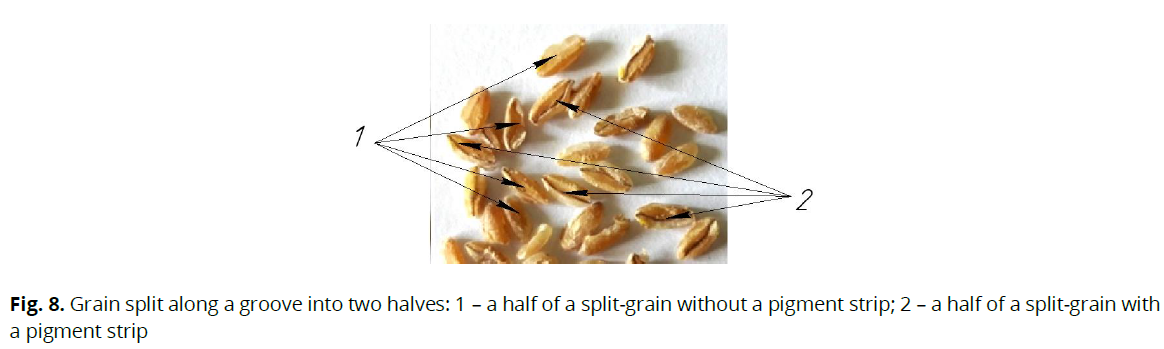

If we assume that the endosperm is homogeneous, then the kernel's split will occur along a plane with a minimum cut area formed along the groove to the kernel's outer surface along the line as shown in Figure 7, which reduces the energy consumption of the process. This assumption found its visual confirmation during the experiment. As seen from Figure 8, when the grain is chipped, a pigment strip is visible on one part of the grain, located in the groove, and not seen on the other.

Fig 8: Grain split along a groove into two halves: 1 – a half of a split-grain without a pigment strip; 2 – a half of a split-grain with a pigment strip

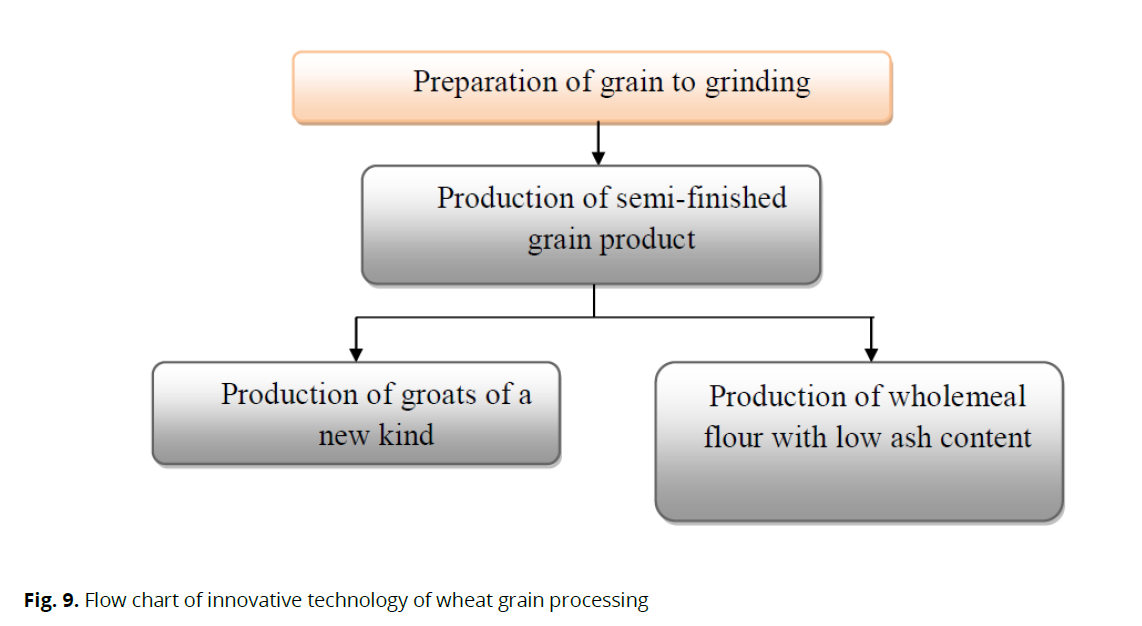

The flow chart of the proposed innovative technology for wheat grain processing is shown in Figure 9. Its essence lies in forming a new grain product at a particular stage of wheat grain processing – a part (lobule) of grain obtained after splitting the grain along the groove. We defined this product as a semi-finished grain product from which it could get groats of a new kind of wholemeal flour with low ash content.

Fig 9: Flow chart of innovative technology of wheat grain processing

Grain preparation for grinding was carried out as follows: the precleaned grain is sent to a cylindrical sifter, on which substandard grain is separated by passing through a 2.2x20 sieve two-grain flows are formed (Table 1). The first stream leaves the riddle 2.8x20, the second stream leaves the riddle 2.2x20.

| Riddle 2.8х20 | Riddle 2.2х20 | Bottom 2.2х20 | |

|---|---|---|---|

| m, g | 4110 | 2861 | 95 |

| % | 58.17 | 40.49 | 1.34 |

Table 1. Grain fractions after screening

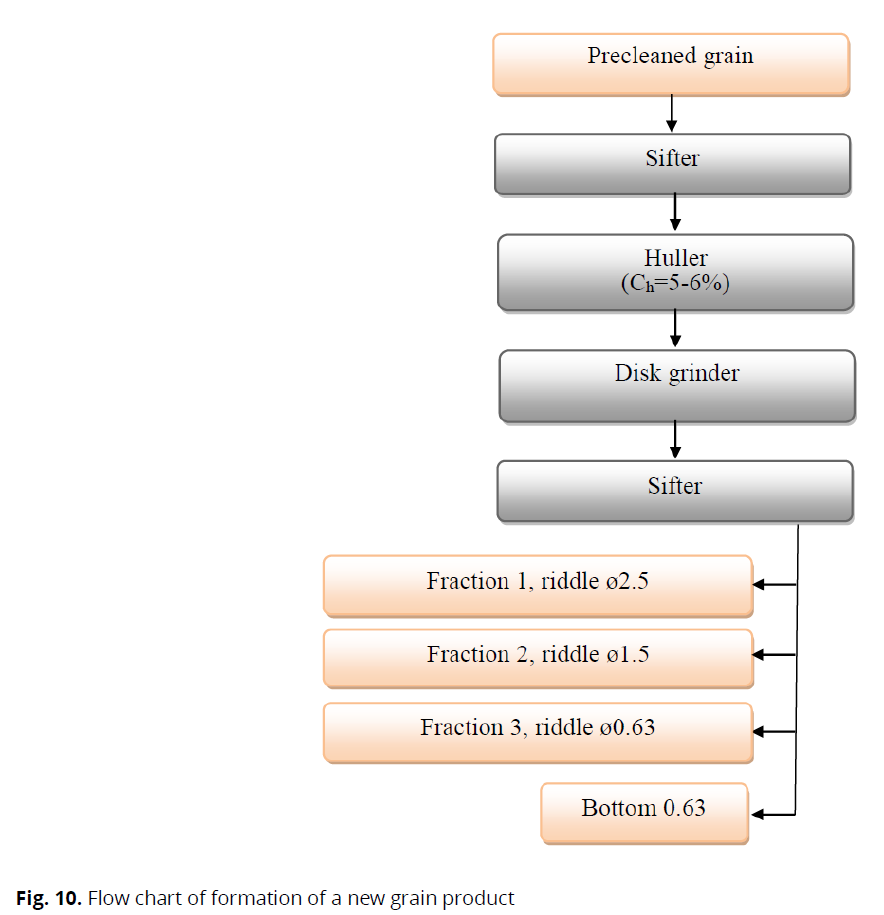

Hulling of each grain flow was carried out in a vertical rotary hulling machine. The degree of grain hulling was set within 5...6 %. The formation of a new grain product is carried out according to the flow chart shown in Figure 10.

Fig 10: Flow chart of formation of a new grain product

According to this flow chart, each stream's hulled grain is fed into a disc grinder, where it is split into two halves along the groove. Samples of the grain split in this way are shown in Figure 8. Then the crushed grain enters the cylindrical sifter, and is divided into fractions: fraction No1 leaving the riddle ø2.5 – the grain is split along the groove into two halves; fraction No2 leaving the riddle ø1.5 and fraction No3 leaving the riddle ø0.63.

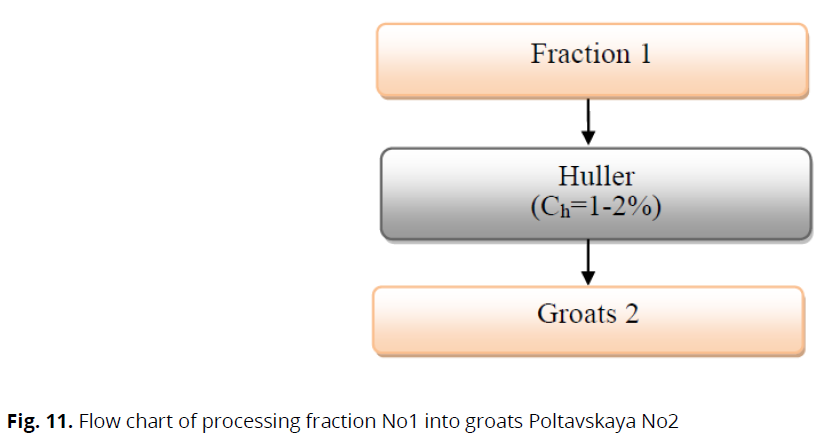

Next, hulling of fraction No1 is carried out in a huller with a smooth cylinder, with the selection of flour in a laboratory air separator according to the scheme shown in Figure 11. Surface treatment of grain by hulling was carried out to remove newly-formed shells and contaminants from the groove's surface. As a result, we obtained cereals corresponding to Poltavskaya No 2 but elongated in shape. Fractions No2 and No3 were processed in the same way. As a result, groats Poltavskaya No4 and Artek were obtained, respectively.

Fig 11: Flow chart of processing fraction No1 into groats Poltavskaya No2

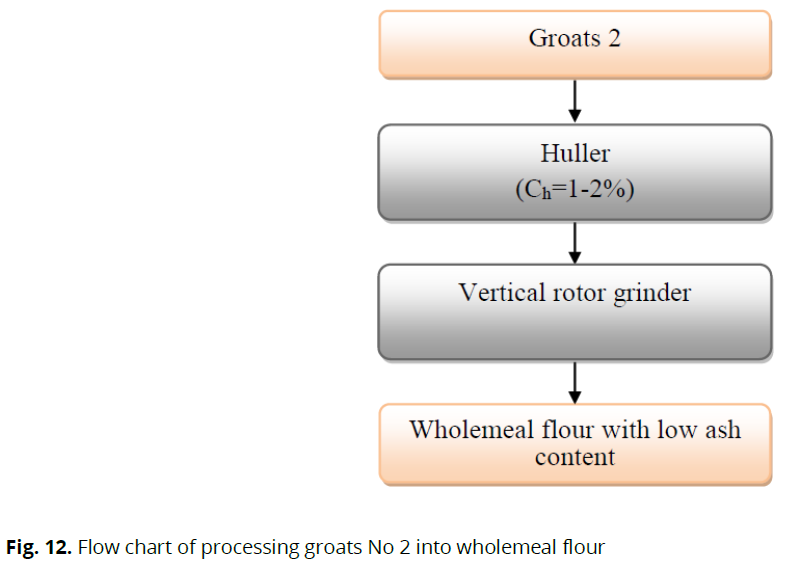

The obtained groats, which correspond to Poltavskaya No 2 can be processed into wholemeal flour with low ash content to expand grain production. The flow chart of processing groats Poltavskaya No2 into wholemeal flour is shown in Figure 12. The groats undergo complementary hulling, taking-off of husking bran и grinding in the vertical rotor grinder.

Fig 12: Flow chart of processing groats No 2 into wholemeal flour

Table 2 shows the outputs of groats Poltavskaya according to the conventional technology (the top line) and new groats and wholemeal flour (the second and third lines, respectively) obtained using a new direction in wheat grain processing technology.

| No. 1, riddle ø3.0 |

No. 2, riddle ø2.5 |

No. 3, riddle ø2.0 |

No. 4, riddle ø1.5 |

Artek, riddle ø0.63 |

Husking bran | Feed screenings | Non-feed screenings | |

|---|---|---|---|---|---|---|---|---|

| groats Poltavskaya | 8% | 43% | 12% | 30% | 5.3% | 1.7% | ||

| New groats | - | 53% | - | 28% | 3.2% | 9% | 5% | 1.8% |

| Flour | - | 48% | - | 28% | 3.2% | 14% | 5% | 1.8% |

Table 2. Manufacturing range

According to what can be seen from Table 2, the output of new groats of elongated shape is 53 %. When processing it, 48 % of wholemeal flour with increased biological value can be obtained without contaminants in the groove of wheat and, during classical processing, get into all types of flour. If the groats Poltavskaya No 4 and Artek are grinded, the wholemeal flour output rises to 79.2 %. Table 3 shows the results of determining the ash content of the products obtained in the research. As shown in Table 3, the ash content of flour from groats No 2 is 0.72; in terms of ash content, this wholemeal flour corresponds to the 1st-grade flour.

| No of the sample | Product | Ash content, % |

|---|---|---|

| 1 | Hulled grain | 1.36 |

| 3 | Husking bran (bottom ø0.63) | 2.23 |

| 4 | Fraction No. 3 (riddle ø0.63) | 1.86 |

| 5 | Fraction No. 2 (riddle ø1.5) | 1.32 |

| 6 | Fraction No. 1 (riddle ø2.5) | 1.11 |

| 7 | Groats No. 2 | 0.96 |

| 8 | Flour from groats No. 2 after repeated hulling | 0.72 |

| 9 | Husking bran | 2.39 |

Table 3. The results of determining the ash content of the derived products

Conclusions

An innovative environmentally friendly technology for wheat grain processing has been proposed, which, due to the formation of a new grain product, makes it possible to obtain a new type of elongated cereal, contaminants being removed from the surface of it; as well as wholemeal flour with low ash content.

The developed equipment allows obtaining in a single stroke up to 53% of ecologically safe groats of a new type, up to 28% of traditional groats Poltavskaya No4, 3.2% of cereals Artek, or, in case of flour production, up to 79.2% of wholemeal flour with an ash content corresponding to the 1st-grade flour.

References

Anderson, J. (2011). Whole grain wheat : effects of peeling and pearling on chemical composition, taste and colour. Second cycle, A1E. Uppsala: SLU, Dept. of Food Science. Available from: http://urn.kb.se/resolve?urn=urn:nbn:se:slu:epsilon-8-1008.

Berkutova, N.S., et al. (1964). O morfologicheskom stroenii obolochek i himicheskom sostave zerna pshenitsyi tselinnogo kraya. Izvestiya vuzov. Pischevaya tehnologiya, 6, 17-19. [in Russian].

Beyer, M., Klix, M.B., et al. (2006). Quantifying the effects of previous crop, tillage, cultivar and triazole fungicides on the deoxynivalenol content of wheat grain – a review. Journal of Plant Diseases and Protection. December (113, 6).Doi: 10.1007/BF03356188).

Bogomolov, A.V., Irkliienko, V.I. (2016). Innovatsionnaya tehnologiya proizvodstva krupyi novogo vida. Visnyk Kharkivskoho natsionalnoho tekhnichnoho universytetu silskoho hospodarstva imeni Petra Vasylenka. Kharkiv. 179, 54-58. [in Russian].

Bohomolov, A.V., Yrklyenko, V.Y. (2018). Novoe napravlenye v tekhnolohyy pererabotky zerna pshenytsy. Visnyk Kharkivskoho natsionalnoho tekhnichnoho universytetu silskoho hospodarstva imeni Petra Vasylenka, Kharkiv, 194, 5-12. [in Ukrainian].

Bohomolov, A.V., Yrklyenko, V.Y. (2019). K voprosu énerhoemkosty yzmelʹchenyya zerna pshenytsy. Visnyk Kharkivskoho natsionalnoho tekhnichnoho universytetu silskoho hospodarstva imeni Petra Vasylenka, 207, 68-75. [in Ukrainian].

Butkovskiy, V.A., Melnikov, E.M. (1989). Tehnologiya mukomolnogo krupyanogo i kombikormovogo proizvodstva. Moscow: Agropromizdat.[in Russian].

Butkovskiy, V.A., Melnikov, E.M. (1990). Mukomolnoe proizvodstvo Moscow. Agropromizdat [in Russian].

Bykova, A.S., Vaschenko, E.V. (2016). Uchebno-metodicheskoe posobie po mikrobiologii dlya studentov napravleniya podgotovki 6091501 ‘Tovarovedenie’. NTU ‘KhPI’ [in Russian].

Edwards, M.A. (2010). Morphological features of wheat grain and genotype affecting flour yield, PhD thesis. Southern Cross University, Lismore, NSW.

Fellers, D.A. (1976). Mechanical. Debraining of whole–kernel wheat. Cereal Chemestry, 53(3), 308-317.

Giambanelli, El., Ferioli, F., et al. (2016). Assessing the effect of traditional hulledwheat processing on bioactive compounds retention. Journal of Cereal Science, 72, 60-68.

Golinko, O.N., Levitskaya, N.P. (2013). Problemyi bezopasnosti i kachestva hlebobulochnyih produktov. Edinoe zdorove i problemyi pitaniya Ukrainy. Nauchnyiy tsentr preventivnoy toksikologii, pischevoy i himicheskoy bezopasnosti imeni akademika L.I. Medvedya MZ Ukrainy. Kiyv. doi: 33273/2663-9726. [in Russian].

Haddad, Y., Mabille, F, et al. (1999). Rheological properties of wheat endosperm with a view on grinding behaviour. Powder Technology, 105, 89-94. (doi:10.1016/S0032-5910(99)00122-9

Konovalov, V.V., Chupshev, A.V., et al. (2015). Obosnovanie ratsionalnyih parametrov ustroystva izmelcheniya kormov skalyivayuschego tipa. “XXI century: resumes of the past and challenges of the present”. Scientific periodical. Penza: PenzSTU Publishing House, 2(24), 196 [in Russian].

Koshak, Zh.V., Minina, E.M., et al. (2013). Fiziko-himicheskie pokazateli kachestva tverdoy pshenitsyi, vyiraschennoy v usloviyah Respubliki Belarus. Naukovi pratsi: Odeska natsionalna akademiya harchovih tehnologiy. Odessa, 44(1), 16-20. [in Russian].

Morgan, A.I. (1966). World wheat – a product of chemical peeling. North-Western Miller, 6(176), 40-43.

Mousia, Z., Edherly, S., et al. (2004). Effect of wheat pearling on flour quality. Food Research International, 37, 449–459.

Roeva, N.N. (2009). Bezopasnost prodovolstvennogo syirya i produktov pitaniya. Uchebno-prakticheskoe posobie. Moscow. MGUTU. Available from: https://studfile. net/preview/6894094 [in Russian].

Uthayakumaran, S., Wrigley, C.W. (2010). Wheat: characteristics and quality requirements. Assessing and Managing Quality. Woodhead Publishing Series in Food Science, Technology and Nutrition. Pp. 59-111. In Cereal Grains. Wrigley, C. (Ed.). Elsevier. Woodhead Publishing

Vereschinskiy, A.P. (2011). Svoystva i osobennosti vzaimodeystviya shlifovalnyih krugov s zernom v protsesse shelusheniya. Hranenie i pererabotka zerna, 11, 62-65. [in Russian].

Vereschinskiy, A.P. (2013). Krupoobrazovanie pri razmole shelushenogo zerna. Hleboproduktyi. Izdatelstvo ‘Hleboproduktyi’. Moscow. [in Russian].

Vereschinskiy, A.P., Shevchenko, A.V. (2012). Ochistka zerna ot primesey v protsesse shelusheniya pri sortovyih pomolah pshenitsyi. Hranenie i pererabotka zerna, 7, 36-37. [in Russian].

Author Info

V.I. Irklienko*, O.V. Bogomolov, I.M. Lukivanov, L.V. Kis-Korkishchenko and P.S. SyromiatnikovCitation: Irklienko, V.I., Bogomolov, O.V., Lukivanov, I.M., Kis-Korkishchenko, L.V., Syromiatnikov, P.S. (2021). Developing environmentally friendly technology for wheat grain processing. Ukrainian Journal of Ecology, 11 (2), 352-359.

Received: 16-Feb-2021 Accepted: 22-Mar-2021 Published: 29-Apr-2021, DOI: 10.15421/2021_122

Copyright: This is an open access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.